Bed profiling system

Our bed profiling system is used to assess the effect flowing water has on mobile sediment beds. It is available with a choice of probes to suit a wide range of applications.

Our bed profiling system is the result of much development work by HR Wallingford to meet the exacting requirements of hydraulic modellers and to ensure a high degree of reliability.

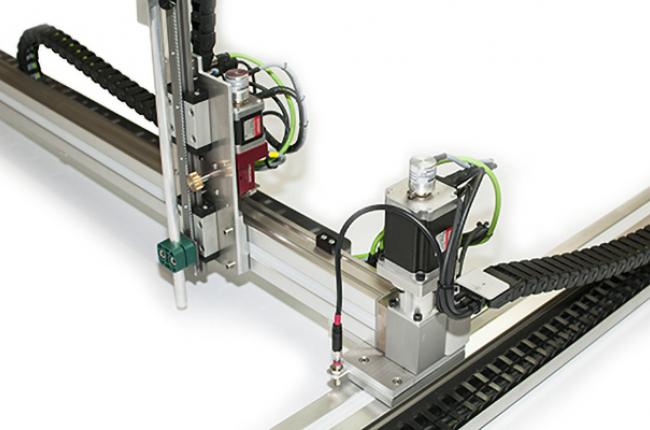

It utilises our traverse system to position the profiler in a 2D or 3D environment.

- utilises our traverse system to position the profiler in a 2D or 3D environment

- operates both with and without water present

- choice of laser or touch-sensitive probes

- accuracy of ±0.5mm vertically and horizontally

- positive non-slip drives

- data stored in ASCII format

- easy to install

Our instrument traverse system

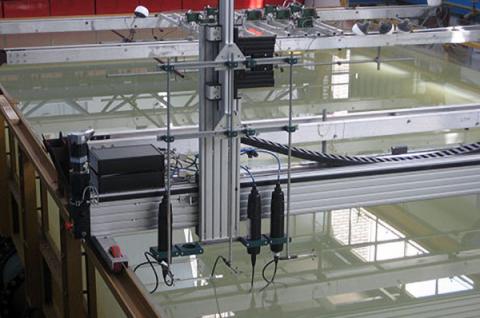

Our instrument traverse system is used to move a range of physical modelling instrumentation to a variety of different positions within a flume or basin in either two or three dimensions.

The instruments are secured to the vertical axis of the system, using a variety of fixings. The vertical axis is attached to a carriage which moves along a fixed horizontal beam to allow positioning of the instruments anywhere within the flume or basin. The traverser can be controlled by a software application that logs the exact time-stamped position of the instruments to an accuracy of ±0.5mm in both vertical and horizontal axes. A stepper motor with an integral encoder is used to drive each axis into position along the carriage using a toothed belt arrangement.

Our Instrument Traverse Systems are individually designed for each application. See Specification for an example of a typical specification.

| Max beam spans | 6 m (x-axis) and 6 m (y-axis) |

|---|---|

| Horizontal travel | Beam length less 200 mm (to allow for carriage and end stops) |

| Beam deflection | 0.5 mm with 4 m support centres |

| Horizontal velocity | Up to 50 mm/s |

| Vertical velocity | Up to 25 mm/s |

| Horizontal resolution | ±0.5 mm |

| Vertical resolution | ±0.5 mm |

| Touch probe: bed contact pressure | 10g over 20 mm diameter |

| Laser probe: maintained height above bed | 80 mm |

| Vertical travel | 1 m |

| Power supply | 220 or 110V AC |

| Standard cable length | 25 m |

| Horizontal beam (x-axis) | |

|---|---|

| Maximum overall length | 6 m |

| Maximum travel | 5.8 m |

| Maximum velocity | 50 mm/s |

| Positional accuracy | ±0.5 mm |

| Horizontal beam (y-axis) | |

| Overall length | 4 m (dual motors required for lengths >2.0m) |

| Travel | 3.8 m |

| Maximum velocity | 50 mm/s |

| Positional accuracy | ±0.5 mm |

| Vertical beam (z-axis) | |

| Travel | 0.6 m or 1.2 m |

| Maximum velocity | 25 mm/s |

| Positional accuracy | ±0.5 mm |

| Lifted weight of instruments | 5 kg |

| Supply voltage | 220V AC or 110V AC |